DIFFERENTIATING TECHNOLOGIES

Engineered Solutions

Internally Developed Technology

Re-Investing in Technology

DIFFERENTIATING WORKMANSHIP

Pride in our work

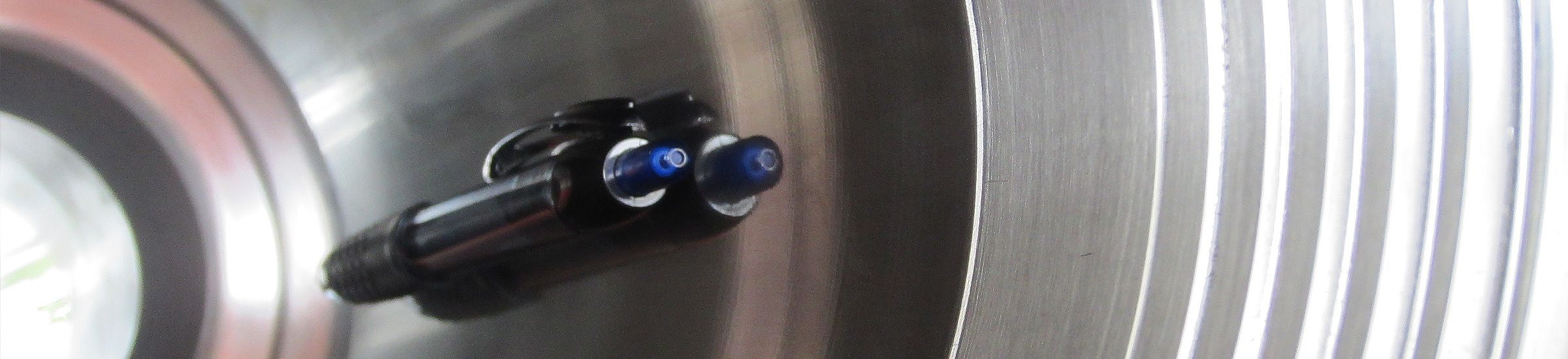

Data Driven Culture

ISO 9001-2015 Certified

Compliant to ISO 14001-2004 /

OSHA 18000-2007

DIFFERENTIATING

LEVEL OF PARTNERSHIP

Customer Focused

Responsive Customer Service

On Time Delivery

Quality

Expert Deep Hole Drilling & Machining Services

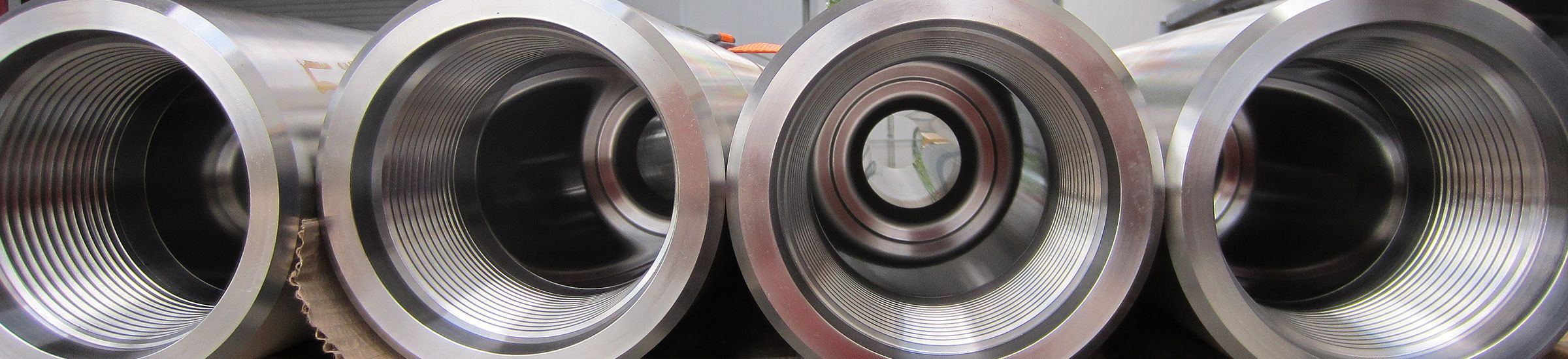

Gun Drilling, Deep Hole Drilling, Honing, Boring & More

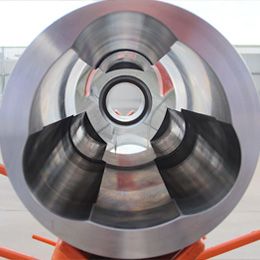

Cobore Inc. is an ISO 9001–2015 Certified facility specializing in precision deep hole drilling and machining services of long parts that require difficult internal features with tight positional tolerances. We guarantee exceptional quality with a focus on our customers' economic drivers, resulting in cost savings and shorter lead times. We are committed to providing the highest level of service and on-time delivery. Through internally developed processes and technology, Cobore can hold incredibly tight positional requirements that far exceed industry standards. Our ability to hold OD to ID concentricity of .010 TIR or better over lengths up to 40 feet can result in significant cost savings on material.

To talk to us about your project and to get an estimate, don't hesitate to contact us today about our deep hole drilling and machining services and capabilities. We offer a range of services (deep hole drilling, gun drilling, honing, and more) and we serve a variety of industries.

Services Offered

Our services and areas of expertise include:

- Deep Hole Drilling

- Gun Drilling

- BTA Drilling

- Pull Boring

- Trepanning

- Honing

- Bottle Bores

- Burnishing

- Reaming

- OD Turning

- Boring

- Centerless Grind

- Straightening

Size Range: .093 to 8.0” ID with lengths up to 40ft

Cobore drills all ferrous and non-ferrous materials. Including Inconel 625 / 718 / 718 NACE / 925, Hastelloy, Datalloy, MP35, Nitronic 50 / 60, 13 Chrome, Duplex 25 Cr, Monel K-500, Non-Mags 15-15HSM / SCF19 / P550 / P580 / P650 / P750, BeCu, Copper, ToughMet, Stainless Steel 304 / 316 / 420 / 450 / 13-8 / 15-5 / 17-4, Titanium, 4140, 4130, 4330, 4340 and many other alloys and plastics.

Contact us today for more information on our services or to request a quote. Our process and expertise uniquely enable us to excel at precision deep hole drilling and boring jobs.

Industries We Serve with Deep Hole Drilling Services

We work with a range of industries by providing deep hole drilling and machining services for a range of applications. These industries include:

- Oil & Gas

- Military

- Aerospace

- Petro-chemical

- And more!

Whatever your industry, reach out today for a quote on your deep hole drilling job. Call us at 713-467-4837.

Our Location & Facility in Houston, Texas

Cobore is located in West Houston on a 10 acre site with 40,000 sqft of manufacturing space. The facility has a full perimeter security fence with access control. Unique to our deephole drilling facility is a Geothermal Climate Control System and a Backyard Wildlife Habitat Certification awarded by Texas Parks and Wildlife Department. Our facility and expertise allow us to provide superior quality, cost savings, and precision. We at excel at jobs that most machine shops would turn away.

Core Values

Challenge: We pursue and enjoy overcoming innovational challenges.

Collaboration: We recognize working in teams generates exponentially greater results.

Pride: We take pride in the intentional efforts and results of our work.

Commitment and Dedication: We follow through with our promises and do it with heart.

Contact Cobore Today for Precision Deep Hole Drilling & Machining Services Nationwide

We take pride in the high-quality, precision work that we do for a range of industries. We can perform jobs that many other companies or machine shops would refuse. Additionally, our methods are designed to give you significant cost savings on material. We are based in Houston, Texas, but we perform work across the United States. Whether you need gun drilling, BTA drilling, bore drilling, honing, or any of the other services we offer, we're here to deliver expert service to you.

Contact us today to request a quote or find about more about our deep hole drilling services and solutions. Just fill out our contact form online or call 713-467-4837.